- Exotic fruits such as mangosteen, rambutan, and dragon fruit require precise temperature, humidity, and handling control to maintain quality and shelf-life.

- Advanced IoT monitoring solutions provide continuous environmental tracking, real-time alerts, and cloud-based analytics to optimize cold storage operations, reduce waste, and ensure compliance from farm to market

Exotic Fruits Require Exotic Care: Optimizing Cold Storage for Sensitive Produce

Understanding the Challenges of Exotic Fruit Cold Storage

Exotic fruits are highly sensitive to temperature fluctuations, high humidity, and physical shock. Even minor deviations during storage or transport can accelerate ripening, cause mold, or compromise flavor and appearance.

Traditional cold storage systems often rely on periodic manual checks, which can miss critical variations. Smart monitoring systems allow continuous environmental tracking, ensuring precise control over storage conditions.

Key requirements for exotic fruit storage include:

- Strict temperature bands tailored to each fruit variety

- Controlled humidity levels to prevent desiccation or fungal growth

- Reduced handling stress and optimized airflow

- Real-time visibility across storage facilities, transportation, and distribution

Advanced Monitoring Technologies for Fresh Produce

Connectivity and Data Collection

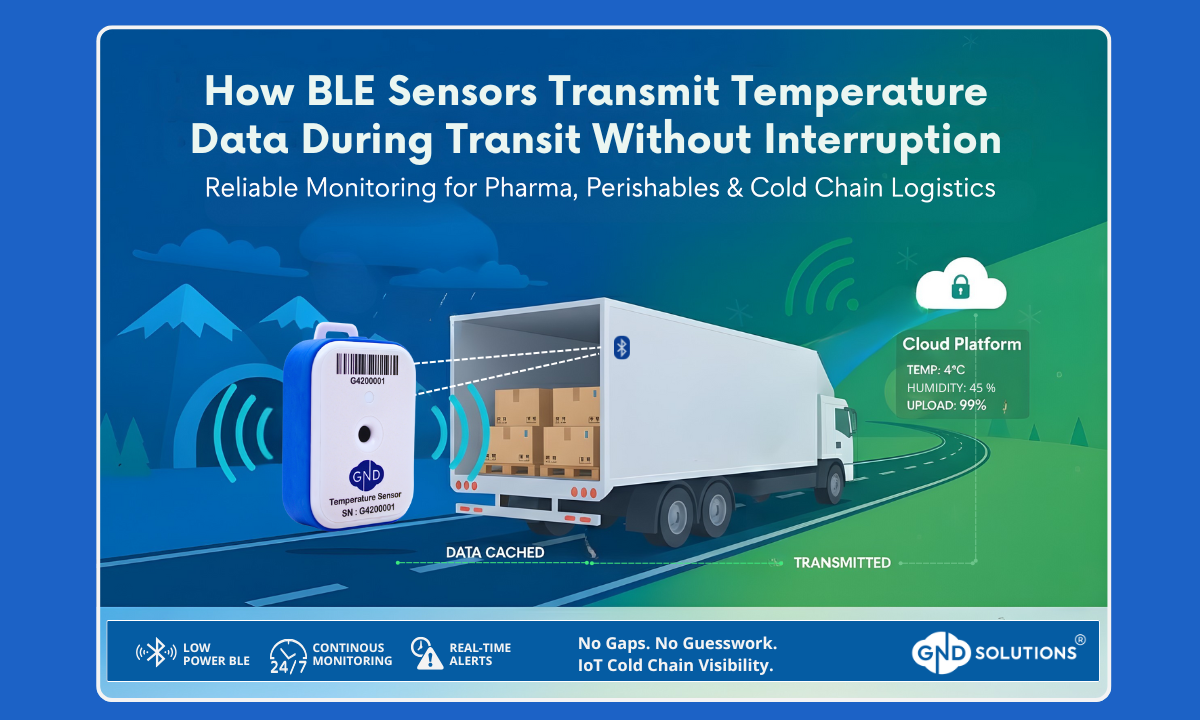

Modern cold storage solutions leverage IoT sensors with wireless communication options suitable for indoor warehouses, refrigerated trucks, and cross-docking environments.

- Short-range wireless technologies support dense indoor sensor networks.

- Long-range IoT connectivity enables real-time monitoring across multiple facilities and transport routes.

- Cloud integration provides dashboards, automated alerts, and predictive analytics to prevent spoilage before it occurs.

Durability and Battery Life

Sensors designed for cold chain applications are rugged and capable of operating across extreme temperatures. Multi-year battery life minimizes maintenance, ensuring uninterrupted data collection and reliable cold storage control.

Security and Compliance

Data security and traceability are critical for compliance with food safety regulations. Modern systems use encryption protocols, secure cloud storage, and automated reporting to support regulatory audits and quality assurance.

Strategic Benefits of Smart Cold Storage

- Continuous environmental monitoring prevents spoilage and extends shelf life.

- Automated compliance reports reduce administrative workload and inspection risks.

- Real-time alerts allow operators to respond immediately to temperature or humidity excursions.

- Predictive insights optimize energy usage and inventory management, supporting sustainability goals.

Use Cases for Exotic Fruit Cold Chain Monitoring

- Tropical fruit import/export requires strict temperature and humidity control.

- Multi-location warehouse monitoring for premium produce distributors.

- Real-time monitoring during refrigerated transport of perishable produce.

- Integration with automated storage and handling systems to minimize handling stress.

FAQs: Optimizing Cold Storage for Exotic Produce

How do IoT sensors maintain consistent conditions?

Sensors provide continuous, high-precision temperature and humidity readings with real-time alerts for early intervention.

Can smart cold storage systems scale for multiple facilities?

Yes. Centralized cloud platforms aggregate data across warehouses, trucks, and distribution hubs, allowing scalable monitoring.

How does this help reduce waste?

By maintaining optimal storage conditions and predicting potential issues, spoilage is minimized, extending shelf-life and protecting product quality.

Conclusion: Protecting Exotic Fruits Through Smart Cold Chain Solutions

Implementing IoT-enabled monitoring and cloud-based analytics ensures exotic fruits arrive at market in peak condition. By combining continuous environmental tracking, automated compliance, and predictive insights, cold storage operators can protect perishable produce, reduce waste, and enhance operational efficiency.

Request a Demo

Get a personalized walkthrough of GND’s Cold Chain platform and see how our sensors, dashboards, and alerts can fit your operations.

Explore more

Smart Monitoring for Airport Cargo and Perishable Logistics

Which Wireless Sensor Fits Your Cold Chain Needs: BLE or LoRaWAN?

How BLE Sensors Transmit Temperature Data During Transit Without Interruption

Optimizing Data Centre Performance with Smart Environmental Monitoring

Meet the GND Solutions Team at Fruit Logistica 2026

Smart & Compliance-Ready: The Future of Cold Chain Monitoring in India (2026)