- In 2026, a cold room without IoT is a financial liability. As Revised Schedule M and ALCOA+ standards tighten, manual logging is no longer audit-compliant, especially in India’s high-heat corridors where a single deviation can trigger ₹20–50 lakh losses.

- GND Solutions provides an IoT digital layer of automated sensors and AI analytics that integrate into your existing infrastructure to deliver 100% tamper-proof reporting, real-time spoilage alerts, and predictive maintenance. Don't just store inventory; secure it with data.

Smart & Compliance-Ready: The Future of Cold Chain Monitoring in India (2026)

The 2026 Reality: Why Infrastructure Alone Is No Longer Enough

India’s cold chain ecosystem has entered a high-growth phase, fueled by pharmaceutical exports, organized retail, and the explosion of quick-commerce. However, as the sector scales, the definition of success has shifted.

Capacity is no longer the competitive advantage visibility is.

In 2026, cold storage infrastructure without intelligent monitoring is a liability. From vaccine stability and dairy distribution to seafood exports, the value of your cargo is only as secure as your data. For businesses across Pharma, FMCG, and Agri-exports, the mission-critical question has evolved: How do you monitor and control your cold chain efficiently, sustainably, and compliantly?

At AICCS 2026, GND Solutions is showcasing the next generation of tracking systems built specifically for India’s high-growth, high-heat industrial corridors.

Why Cold Chain Monitoring Is Critical in 2026

India continues to experience significant cold chain losses due to temperature inconsistencies and fragmented logistics networks. At the same time, regulatory expectations are rising.

Regulatory Pressure Is Increasing

The legal landscape in India has tightened, making digital oversight a necessity rather than an option:

- Revised Schedule M: Strengthens pharmaceutical compliance requirements for manufacturing and storage.

- FSSAI Amendments: Emphasize digital traceability and accountability in the food supply chain.

- WHO-GDP Audits: Require uninterrupted temperature documentation for global pharmaceutical distribution.

- ALCOA+ Principles: Demand that records are Attributable, Legible, Contemporaneous, Original, and Accurate.

- Manual Logging Risks: Handwritten logs are increasingly viewed by auditors as a significant compliance risk.

Manual Logging vs IoT-Based Monitoring

Traditional manual temperature logging relies on periodic checks, handwritten records, and delayed corrective action. This system is inherently reactive and prone to human error.

In contrast, IoT-based monitoring provides continuous real-time tracking and automated deviation alerts. Connected monitoring platforms generate secure, time-stamped, tamper-resistant data aligned with global audit requirements. As compliance frameworks strengthen, digital monitoring is rapidly replacing paper-based processes.

Market Expansion Is Accelerating

The demand for precision monitoring is scaling alongside industry growth:

- Pharmaceutical and vaccine distribution networks are expanding into deeper rural pockets.

- Tier 2 and Tier 3 cities are rapidly increasing their frozen storage capacity.

- Meat and seafood exporters must meet strict global standards for international trade.

- Quick-commerce requires precise micro-fulfillment monitoring to maintain the "10-minute" promise safely.

The Cost of a Single Temperature Deviation

A short temperature excursion is not just a technical error; it is a massive financial blow:

- ₹20–50 lakh batch losses in pharmaceutical batches or high-value exports.

- Shipment rejection at major ports, leading to logistics deadlocks.

- Regulatory penalties or the potential suspension of operating licenses.

- Long-term brand damage that can take years to recover.

Most facilities have refrigeration. Few have intelligent, connected monitoring.

What GND Solutions Delivers

GND Solutions provides IoT-enabled cold chain monitoring and connected intelligence systems designed to add visibility and control to existing refrigeration infrastructure. Rather than replacing cold storage systems, GND enhances them with intelligent monitoring and analytics.

GND Core Capabilities

- Real-time temperature and humidity monitoring.

- Industrial-grade sensors and data loggers built for rugged environments.

- Cloud-based multi-site dashboards for centralized management.

- Automated alarm notifications via SMS, Email, or App for any deviations.

- AI-driven temperature trend analytics.

- Predictive maintenance insights to prevent equipment failure.

- Audit-ready digital compliance reports.

- Refrigerated fleet and reefer container monitoring.

Using industrial communication protocols such as Modbus, LoRaWAN , and BLE connectivity , GND Solutions enables seamless integration across warehouses, manufacturing plants, refrigerated transport, and distribution networks. Monitoring becomes proactive rather than reactive. By enabling early detection of temperature deviations and equipment stress patterns, we help businesses reduce spoilage risk and protect high-value inventory.

What Is Cold Chain Monitoring?

Cold chain monitoring refers to the continuous tracking and documentation of temperature and environmental conditions across storage and transportation environments for temperature-sensitive products. Using IoT-enabled sensors, connected dashboards, and automated alert systems, modern monitoring platforms provide real-time visibility and digital traceability. This ensures regulatory compliance, protects product efficacy, and reduces losses caused by temperature excursions.

End-to-End Cold Chain Visibility

Cold Storage & Warehousing Monitoring

GND Solutions supports:

- Multi-commodity cold storage facilities.

- Pharmaceutical cold rooms and vaccine storage environments.

- Frozen food warehouses and blast freezers.

- High-bay automated storage systems.

Centralized dashboards provide unified control across multiple facilities with continuous environmental tracking.

Refrigerated Transport & Export Monitoring

Risk increases significantly during transportation. GND monitoring systems enable:

- Real-time temperature tracking in refrigerated trucks.

- Reefer container monitoring for international shipping.

- Inter-city pharmaceutical shipment monitoring.

- Agri-export consignment tracking and port-bound shipment visibility

Instant alerts ensure corrective action can be taken before product integrity is compromised.

Last-Mile & Micro-Fulfillment Monitoring

With the growth of quick-commerce, last-mile temperature control is critical. GND Solutions enables:

- Live monitoring of small refrigerated vehicles

- Distributed fleet visibility.

- Instant deviation alerts for delivery personnel and hub managers.

- Centralized control of decentralized operations.

Data-Driven Cold Chain Intelligence

Modern cold chain management goes beyond simple alarms. With advanced analytics and centralized dashboards, businesses can:

1. Identify recurring fluctuation patterns to fix structural insulation issues.

2. Optimize refrigeration energy performance to lower operational costs.

3. Detect early signs of equipment stress for better maintenance scheduling.

4. Strengthen audit readiness with a permanent digital paper trail.

5. Reduce spoilage and shrinkage directly affecting the bottom line.

Monitoring transforms into a strategic control system that enhances both operational efficiency and regulatory compliance.

Why Maharashtra Is a Strategic Smart Cold Chain Market

Maharashtra plays a pivotal role in India’s temperature-sensitive supply chains. It connects pharmaceutical manufacturing hubs in Pune and Aurangabad with expanding agri networks in Nashik and critical export routes via JNPT.

This concentration of pharma production, agri exports, and port logistics makes Maharashtra one of India’s most strategically important cold chain markets. However, geography presents challenges. Rising ambient temperatures across the Deccan Plateau reduce the effectiveness of passive cooling methods. High-density industrial corridors experience significant heat stress during loading and unloading cycles.

In such high-heat, high-compliance environments, intelligent monitoring is essential. GND Solutions’ technology is optimized specifically for these demanding conditions, delivering real-time visibility across the entire state.

Meet GND Solutions at AICCS 2026 – Booth B-14

At AICCS 2026 in Pune, GND Solutions is showcasing advanced IoT-based cold chain monitoring and connected compliance systems. Visitors at Booth B-14 can explore:

- Unified, all-in-one monitoring dashboards.

- Industrial-grade sensor integrations.

- Refrigerated fleet tracking solutions

- Predictive analytics and compliance reporting tools.

Designed For: Pharmaceutical Manufacturers, Dairy & Ice Cream Producers, Meat & Seafood Exporters, Frozen Food Brands, FMCG & Retail Chains, and Agri Exporters.

FAQ – Cold Chain Monitoring & GND Solutions

What are cold chain solutions?

Cold chain solutions refer to systems that maintain and monitor temperature-sensitive products across storage and transportation environments. These include temperature-controlled facilities, refrigeration systems, refrigerated transport, and IoT-based real-time monitoring platforms that ensure product integrity from production to final delivery.

Why is cold chain infrastructure critical for pharmaceutical companies?

Pharmaceutical products such as vaccines and biologics require strict temperature control, often between 2°C - 8°C or lower. Even minor deviations can compromise product efficacy, lead to regulatory non-compliance, and result in financial losses. Continuous digital temperature monitoring and compliance-ready data logging are essential for meeting GDP and Schedule M requirements.

Which industries benefit most from modern cold chain monitoring systems?

Industries that rely heavily on temperature-controlled supply chains include pharmaceutical manufacturers, dairy and ice cream producers, meat and seafood exporters, frozen food brands, FMCG and retail chains, e-commerce grocery platforms, agri exporters, FPOs, and seed and horticulture businesses.

How does IoT improve cold chain management?

IoT-based cold chain monitoring systems provide continuous temperature and humidity tracking, automated deviation alerts, remote multi-site dashboards, predictive maintenance insights, and audit-ready digital reports. This reduces product loss, minimizes manual errors, strengthens compliance, and improves operational efficiency.

What does GND Solutions offer in the cold chain industry?

GND Solutions delivers IoT-enabled cold chain monitoring systems including industrial-grade sensors, connectivity modules, cloud dashboards, AI-driven analytics, and compliance-ready reporting tools designed for temperature-sensitive supply chains.

Does GND Solutions support pharmaceutical cold chain compliance?

Yes. GND Solutions’ monitoring systems provide secure environmental data logging, digital traceability, and audit-ready reporting aligned with pharmaceutical regulatory standards.

Why should businesses upgrade from traditional cold storage monitoring systems?

Traditional monitoring methods often rely on manual logging and isolated temperature devices, which create visibility gaps and increase compliance risks. Upgrading to IoT-based cold chain monitoring enables continuous tracking, automated alerts, centralized reporting, and audit-ready documentation providing stronger protection against spoilage, regulatory penalties, and shipment rejection.

Request a Demo

Get a personalized walkthrough of GND’s Cold Chain platform and see how our sensors, dashboards, and alerts can fit your operations.

Explore more

Exotic Fruits Require Exotic Care: Optimizing Cold Storage for Sensitive Produce

Smart Monitoring for Airport Cargo and Perishable Logistics

Which Wireless Sensor Fits Your Cold Chain Needs: BLE or LoRaWAN?

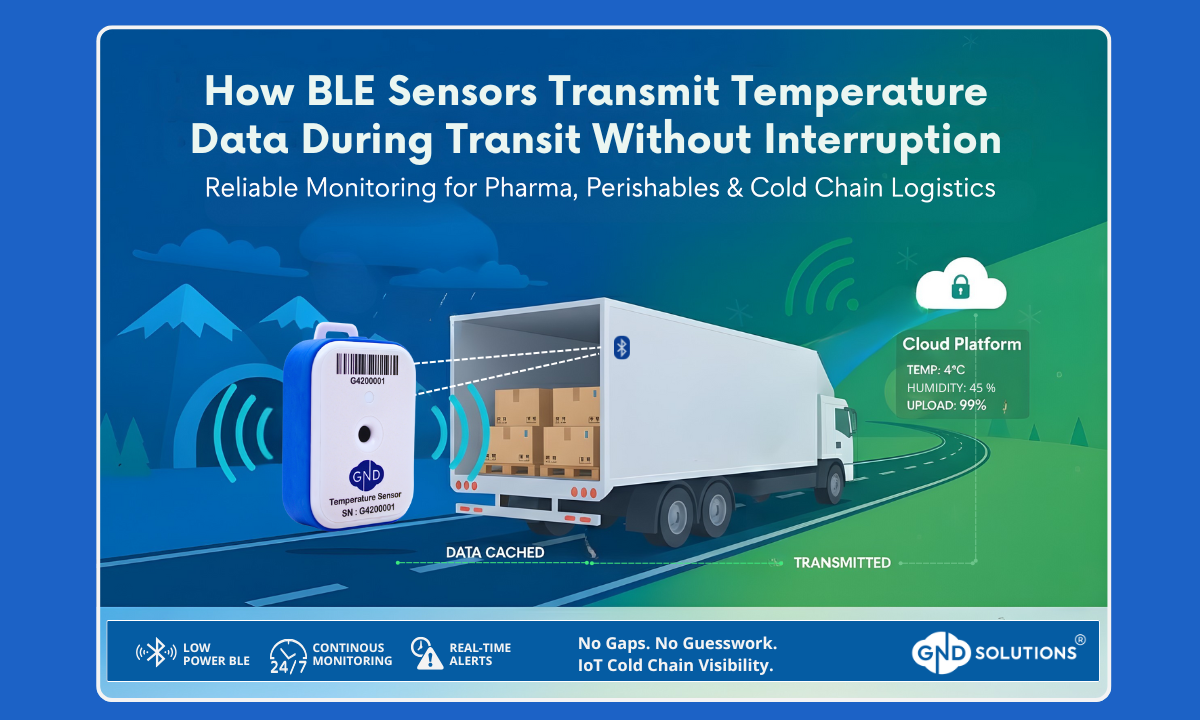

How BLE Sensors Transmit Temperature Data During Transit Without Interruption

Optimizing Data Centre Performance with Smart Environmental Monitoring

Meet the GND Solutions Team at Fruit Logistica 2026