- Cold chain monitoring for fruit refers to the continuous tracking of temperature, humidity, CO₂, and handling conditions throughout storage and transport. Global fruit supply chains demand precise control of these parameters to protect quality and shelf life.

- GND Solutions delivers an end-to-end cold chain monitoring platform combining multi-parameter IoT sensors, global connectivity, and cloud-based analytics to improve visibility, help reduce waste, and support compliance across fruit logistics operations.

Meet the GND Solutions Team at Fruit Logistica 2026

Understanding the Challenges of Global Fruit Logistics

Modern fruit supply chains span multiple countries, transport modes, and regulatory frameworks. Exporters and logistics providers must balance quality preservation, cost efficiency, and compliance across complex operations.

Fresh fruits are highly sensitive to temperature fluctuations, moisture imbalance, elevated CO₂ levels, and physical shock. Even minor deviations during storage or transit can accelerate ripening, cause bruising, promote mold growth, and shorten shelf life.

Industry research estimates that 20–30% of fresh produce is lost globally each year, with a significant share linked to cold chain failures and handling damage during transportation and storage.

Despite these risks, many organizations continue to rely on manual inspections and fragmented systems, limiting real-time visibility and proactive intervention. This often leads to:

- High spoilage and rejection rates

- Limited end-to-end shipment visibility

- Inconsistent controlled-atmosphere management

- Undetected vibration and handling damage

- Complex compliance documentation

- Rising refrigeration and operational costs

These challenges directly impact profitability, brand reputation, and customer trust.

Advanced Cold Chain Monitoring Technologies for Fruit Supply Chains

At Fruit Logistica 2026, GND Solutions will showcase its end-to-end IoT cold chain monitoring ecosystem, integrating hardware, connectivity, and analytics into a unified operational environment.

The platform provides continuous visibility across storage, transportation, and distribution networks, enabling data-driven decision-making throughout the fruit supply chain.

Connectivity and Data Collection

GND Solutions’ monitoring architecture supports global logistics operations through flexible and secure connectivity options:

- Short-range networks for dense cold storage and warehouse deployments

- Cellular, NB-IoT, and LPWAN technologies for international shipment tracking

- Secure cloud integration for real-time dashboards, alerts, and reporting

This design ensures uninterrupted data flow from origin to destination, enabling complete visibility throughout the supply chain.

Multi-Parameter Sensor Performance

GND’s industrial-grade sensors are engineered for reliable operation in refrigerated and controlled-atmosphere environments. They continuously monitor:

- Temperature to maintain cold chain integrity

- Humidity to prevent moisture-related quality loss

- CO₂ levels to manage ripening and atmosphere control

- Vibration and shock to detect handling and transit damage

Rugged design and long battery life minimize maintenance while ensuring consistent monitoring throughout extended shipments.

Security, Compliance, and Data Integrity

As regulatory requirements and buyer standards continue to evolve, maintaining data integrity is critical. GND Solutions provides enterprise-grade security and traceability features, including:

- Encrypted data transmission to protect sensitive shipment data

- Secure cloud infrastructure for reliable storage and access

- Automated, audit-ready reporting to simplify compliance checks

- End-to-end shipment traceability across the entire supply chain

Strategic Benefits of GND Cold Chain Monitoring

Industry studies indicate that temperature excursions and handling issues are among the leading causes of refrigerated cargo claims in fresh produce logistics.

By implementing an integrated hardware-to-cloud monitoring solution, fruit exporters and logistics providers can achieve:

- Reduced spoilage and quality loss

- Lower insurance claims and shipment rejections

- Faster response to temperature or atmosphere deviations

- Improved controlled-atmosphere management

- Optimized energy usage and inventory planning

- Enhanced sustainability performance through waste reduction

This approach transforms cold chain monitoring from a reactive process into a strategic quality and risk management function, helping organizations protect product integrity, reduce costs, and meet regulatory standards.

Use Cases for Fruit Logistics and Export Operations

GND Solutions supports a wide range of fresh produce and fruit logistics applications, including:

- Tropical and exotic fruit export and import

- Controlled-atmosphere container monitoring

- Multi-location cold storage management

- Reefer truck and rail shipment tracking

- Distribution center quality assurance

- Integration with automated handling and logistics systems

These use cases demonstrate how continuous visibility helps protect product quality, reduce losses, and improve operational efficiency across complex global supply chains.

FAQs: GND Cold Chain Monitoring at Fruit Logistica 2026

Where can I meet GND Solutions at Fruit Logistica 2026?

You can meet the GND Solutions team at Hall 26, Stand C-10 in Berlin, where live demonstrations of the cold chain monitoring platform and global sensor dashboards will be available.

How is CO₂ monitored in fruit transportation?

CO₂ monitoring in fruit transport is performed using industrial-grade sensors installed inside containers, cold storage rooms, or reefer units. These sensors continuously measure CO₂ concentration and transmit data in real time via cellular or NB-IoT connectivity to a cloud platform, enabling remote visibility and controlled-atmosphere management throughout transit.

How does real-time monitoring help reduce fruit spoilage and cargo claims?

Many spoilage incidents and refrigerated cargo claims are linked to undetected temperature excursions, atmosphere imbalance, or handling damage during transit. Real-time monitoring enables early alerts when conditions deviate from acceptable thresholds, allowing corrective action during storage or transport rather than after delivery.

What parameters do GND cold chain sensors monitor?

GND sensors continuously track multiple environmental and handling parameters, including:

Temperature, Relative humidity, CO₂ levels, Vibration and physical shock. This multi-parameter approach provides a comprehensive view of cold chain integrity from origin to destination.

Does GND’s monitoring system support export and compliance requirements?

Yes. The platform generates secure, audit-ready reports that support export documentation, customer quality standards, and regulatory audits. End-to-end data traceability helps demonstrate proper cold chain handling and chain-of-custody across international fruit shipments.

Can the platform be used for international fruit shipments?

Yes. GND Solutions is designed for cross-border fruit logistics, supporting multi-country shipments with global connectivity, cloud-based dashboards, and centralized monitoring across sea, road, rail, and cold storage environments.

Why is multi-parameter monitoring important for fruit logistics?

Fruit quality is influenced by more than temperature alone. Monitoring humidity, CO₂, and handling conditions alongside temperature provides deeper insight into ripening behavior, shelf-life risk, and transit damage, especially for long-haul and controlled-atmosphere shipments.

Conclusion: Protecting Exotic Fruits Through Smart Cold Chain Solutions

Implementing IoT-enabled monitoring and cloud-based analytics ensures exotic fruits arrive at market in peak condition. By combining continuous environmental tracking, automated compliance, and predictive insights, cold storage operators can protect perishable produce, reduce waste, and enhance operational efficiency.

Request a Demo

Get a personalized walkthrough of GND’s Cold Chain platform and see how our sensors, dashboards, and alerts can fit your operations.

Explore more

Exotic Fruits Require Exotic Care: Optimizing Cold Storage for Sensitive Produce

Smart Monitoring for Airport Cargo and Perishable Logistics

Which Wireless Sensor Fits Your Cold Chain Needs: BLE or LoRaWAN?

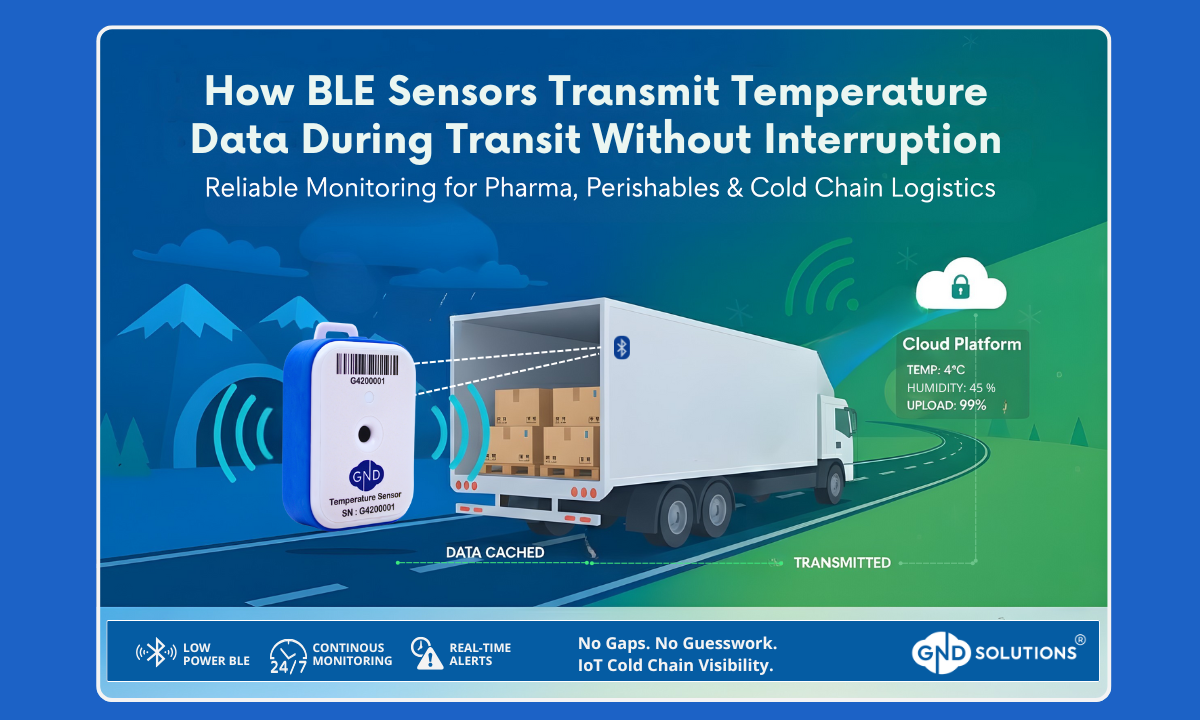

How BLE Sensors Transmit Temperature Data During Transit Without Interruption

Optimizing Data Centre Performance with Smart Environmental Monitoring

Smart & Compliance-Ready: The Future of Cold Chain Monitoring in India (2026)